+86 183 6235 7257

|

Sulfurization Method |

Suggested Usage Ratio |

Sulfurization Temperature |

Sulfurization Time |

|

|

XJ-25A |

XJ-25B |

|||

|

Molding |

0.4%-0.6% |

0.8%-1.0% |

110℃-130℃ |

Depending on product needs |

|

Extrusion |

0.4%-0.6% |

0.8%-1.0% |

200℃-500℃ |

|

Mixing method 1:Take 20KG adhesive as an example:

A agent: 0.4% × 20KG = 80 grams

Agent B: 0.8% × 20KG = 160 grams

First take 10KG of silica gel and A agent 80 grams of mixing uniformly, and then static cooling. Then take 10KG of silica gel and 160 grams of agent B and mix it evenly, and leave it to cool. Before vulcanization molding, take equal ratio of A and B rubber mixed with each other evenly can be used for vulcanization molding operation.A rubber and B rubber mixed with each other, need to be used up within 4 hours to 8 hours to prevent room temperature cross-linking. If A rubber and B rubber need to be stored for a longer time after mixing each other, it is necessary to add delaying agent, the amount used depends on the need, but the more delaying agent, the slower the speed of sulfurization.

Mixing method 2:Take 20KG adhesive as an example:

First, put 20KG silicone in the glue machine mixing to soften, color glue and other additives can be added in the process, take the softened 20KG silicone and B agent 160 grams of mixing uniformly, and then leave it to cool down. Then take 80g of A agent and add it into 20KG silica gel which has been mixed with B agent in batches, mixing evenly. After standing and cooling, it can be used for molding operation.

Mixing process should try to keep the refiner roller does not exceed 35 degrees, it is recommended that the refiner with cooling water circulation, high temperatures should be used to control the ambient temperature of air conditioning and other measures to reduce the temperature of the roller.

Precautions

1, It is forbidden to have nitrogen, phosphorus, sulfur, lead, multi-ethynyl group and other substances to join, because the above substances can make platinum poisoning failure, and can not achieve the purpose of cross-linking. 1. It is forbidden to have nitrogen, phosphorus, sulfur, lead, multi-ethynyl group and other substances to join, because the above substances can make platinum poisoning failure, and can not achieve the purpose of cross-linking.

2, Some silicone color glue will also lead to platinum poisoning failure and can not be used, so in the choice of vulcanizing agent to produce, must be a small test to confirm the feasibility of the use.

3, After adding the platinum vulcanizing agent of silicone mixing, it is recommended to vulcanize the molding within 4-8 hours to prevent room temperature cross-linking. If you need to extend the preservation time, you can add a little delay agent (need to be purchased separately).

4, When there is hydrogen silicone oil in the silicone, the extruded products are easy to produce air bubbles. When there is hydrogen silicone oil in silicone, when mixing A agent alone, the rubber will be dead.

5, When there is hydrogen silicone oil in the silicone, when mixing A agent alone, the rubber will be dead.

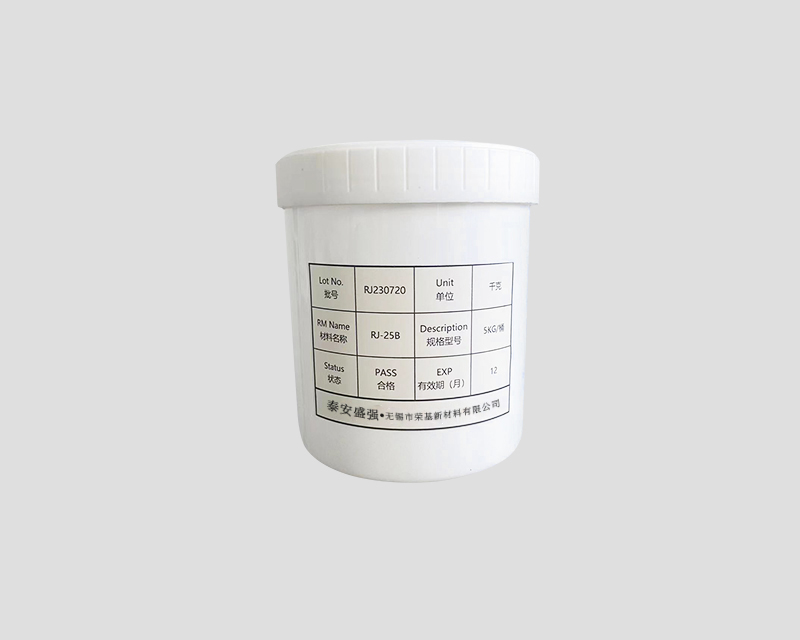

Product Appearance

A agent: transparent gel B agent: transparent powder

Packing

1KG, 5KG, 20KG / Tank

Preservation Period:Three months

Storage and Transportation

1, Avoid high temperature, direct sunlight, acidic substances, metal oxides, amines and flammable materials, should be stored in a dry, cool place, room temperature below 25 degrees.

2, This product is non-dangerous goods, and can be transported according to general chemicals.

Hotline

Hotline